There are many factors affecting the safety failure of the lithium-ion energy battery system, such as: excessive charging and discharging, short circuit, collision, high temperature, loose connection, etc. Among them, there are many safety accidents caused by loose connections, and the loose connections have difficulties such as large uncertainty and difficult diagnosis. Therefore, research on the connection technology of lithium-ion energy storage battery systems will improve the connection performance of lithium-ion battery systems, Process optimization and process management strengthening of manufacturing engineering are of great significanceLaswer welding is widely used in energy storage system and electric vehicle.

what‘s the advantage of laser welding?

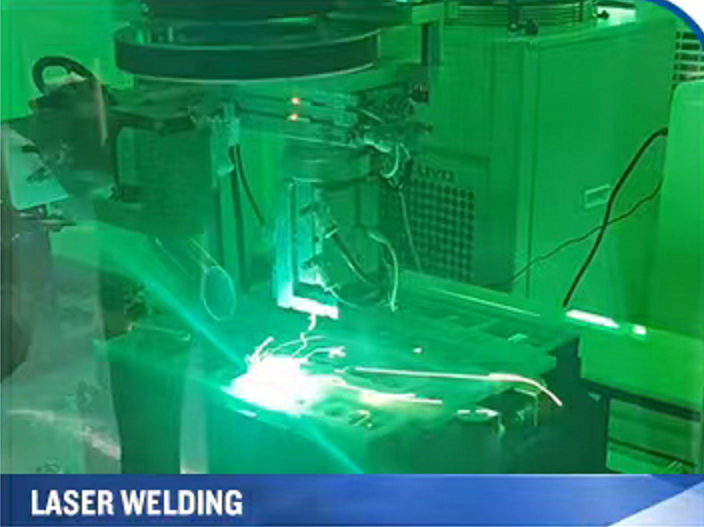

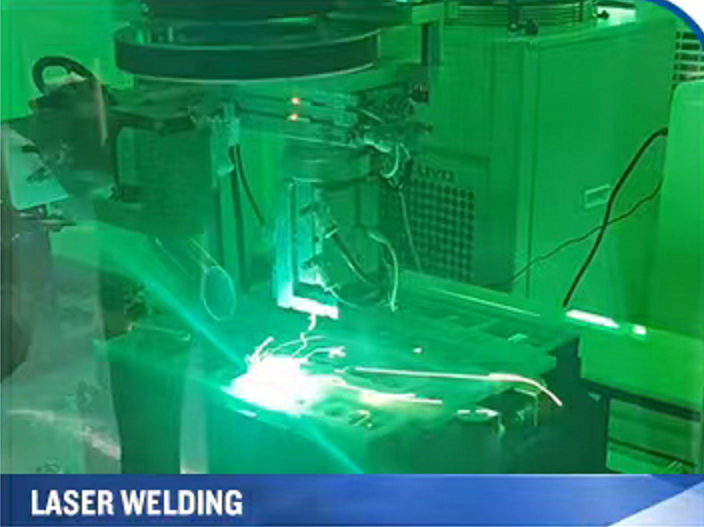

Laser welding is a non-contact welding process in which the heat generated by a laser beam heats the workpiece and simultaneously joins multiple layers of metal, usually within milliseconds. Generally used for welding of electrolyte containers, connectors and busbars. As a non-contact welding process, laser welding has corresponding advantages for the connection of lithium-ion battery systems. Since laser welding has the smallest heat-affected zone in all welding processes and can be applied to the connection of multi-layer sheets, laser welding is considered to be the most effective welding process for lithium-ion battery systems. Laser welding applications are shown in Figure 5. .picture

There are many factors affecting the laser welding process, mainly including the swing frequency and amplitude related to the swing, the power frequency and pulse time related to the laser, and the moving speed and focus range related to the equipment. Shaikh et al. used a 150W Quasi-CWIR laser to weld copper tabs to steel cylindrical battery boxes by laser welding, and studied the influence of relevant process parameters on mechanical, electrical and thermal properties. It was found that the laser related parameters, power, frequency and pulse time are positively correlated with the shear strength of the sample, while the pulse time is negatively correlated, so the optimal process parameters are optimized, the power is 40%, the speed is 500mm/min, Pulse time 2ms, frequency 50Hz.

However, relevant research workers have also found that laser welding requires high precision in the assembly position of the workpiece, and requires welding materials to meet high reflectivity, high thermal conductivity and other properties, which makes the implementation and application of laser welding in lithium-ion battery connections more difficult. . Through the continuous exploration of the majority of workers, the corresponding corresponding experience was finally summed up. When welding the tab to the terminal, the tab needs to be thinner than the battery box terminal, and the processing parameters need to be strictly controlled to provide enough welding energy without penetrating the battery box. Brand et al. found that since the molten pool of laser welding is small and the gap tolerance is small, better results can be obtained by tightening the tabs on the battery when welding the tabs.

#VTC Power Co.,LTD #Lithium ion battery energy storage #lithium-ion battery #battery box #electric vehicle battery.